Grain Dryers

Description

Seed drying facilities from a few kilograms to a few tons:

Seed drying is a particularly sensitive operation because it must lower the water content to prevent the growth of molds, and reduce the grains respiration, without compromising their germinating capacity.

Controlling climatic parameters, temperature and hygrometry is thus essential.

Several techniques are used such as hot air blowing, very energy consuming in natural gas or fuel of petroleum origin.

In our grain dryers and drying chambers, we offer a thermodynamic principle based on dry air blowing, with a condition of equilibrium with the required final water content, in a closed loop. Air drying is ensured by a refrigeration system with an excellent energy performance coefficient. Maintaining the installation is easy.

Our grain dryers are tailor-made, based on a number of input data: quantity, type and initial and final water content of seeds, requested drying time .

We can process up to several tons in 24h.

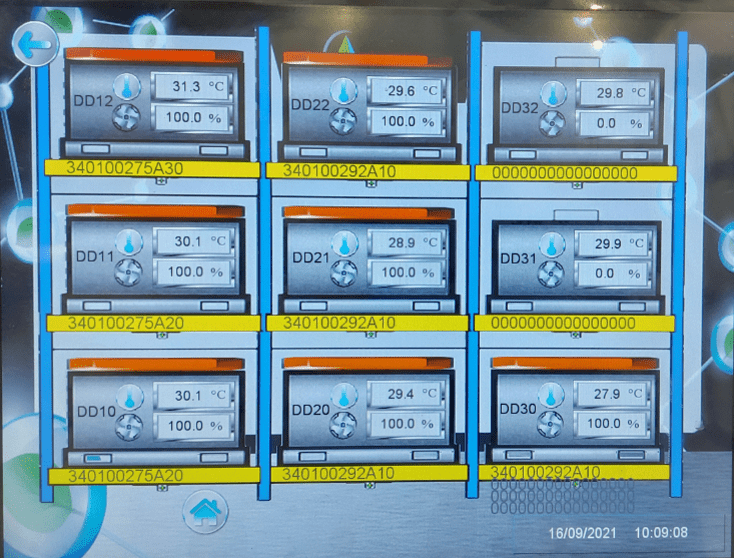

At the other end, the drying cabinets have a capacity of 1 kg to 50 kg. They can also be custom designed.

There are 3 standard sizes of grain drying ovens: 2 kgs to dry over 24 hours, 40 kgs to dry over 24h, 80 kgs to dry over 48h.

Thanks to STRADER expertise, climatic chambers manufacturer since 35 years, all the materials used are non-corrodible and completely inert towards plants.

Drying chambers and grain dryers are subject to extensive functional testing, commissioning and training of users and maintenance personnel.